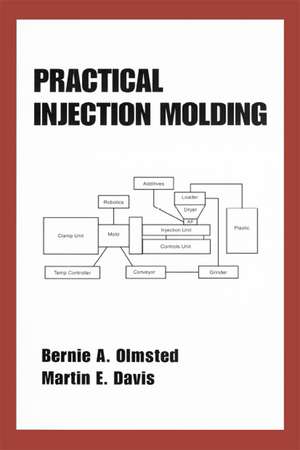

Practical Injection Molding: Plastics Engineering

Editat de Bernie A. Olmsted, Martin Davisen Limba Engleză Hardback – 14 mar 2001

Din seria Plastics Engineering

- 15%

Preț: 532.43 lei

Preț: 532.43 lei -

Preț: 440.45 lei

Preț: 440.45 lei - 15%

Preț: 490.88 lei

Preț: 490.88 lei - 18%

Preț: 1072.29 lei

Preț: 1072.29 lei - 18%

Preț: 1986.92 lei

Preț: 1986.92 lei - 18%

Preț: 1617.60 lei

Preț: 1617.60 lei - 15%

Preț: 535.56 lei

Preț: 535.56 lei - 18%

Preț: 3098.50 lei

Preț: 3098.50 lei - 18%

Preț: 3108.67 lei

Preț: 3108.67 lei - 18%

Preț: 1985.42 lei

Preț: 1985.42 lei - 18%

Preț: 2546.13 lei

Preț: 2546.13 lei - 18%

Preț: 2387.63 lei

Preț: 2387.63 lei - 18%

Preț: 1549.04 lei

Preț: 1549.04 lei - 18%

Preț: 3103.82 lei

Preț: 3103.82 lei - 18%

Preț: 2089.76 lei

Preț: 2089.76 lei - 18%

Preț: 2672.98 lei

Preț: 2672.98 lei - 29%

Preț: 2444.19 lei

Preț: 2444.19 lei - 29%

Preț: 1763.09 lei

Preț: 1763.09 lei - 29%

Preț: 2434.36 lei

Preț: 2434.36 lei - 29%

Preț: 2609.15 lei

Preț: 2609.15 lei - 29%

Preț: 1844.52 lei

Preț: 1844.52 lei - 26%

Preț: 1795.20 lei

Preț: 1795.20 lei - 22%

Preț: 448.25 lei

Preț: 448.25 lei - 22%

Preț: 443.46 lei

Preț: 443.46 lei

Preț: 1355.18 lei

Preț vechi: 1652.66 lei

-18%

Puncte Express: 2033

Preț estimativ în valută:

239.67€ • 283.62$ • 208.98£

239.67€ • 283.62$ • 208.98£

Carte tipărită la comandă

Livrare economică 03-17 aprilie

Specificații

ISBN-13: 9780824705299

ISBN-10: 0824705297

Pagini: 232

Ilustrații: illustrations, references

Dimensiuni: 156 x 234 x 17 mm

Greutate: 0.49 kg

Ediția:1

Editura: CRC Press

Colecția CRC Press

Seria Plastics Engineering

ISBN-10: 0824705297

Pagini: 232

Ilustrații: illustrations, references

Dimensiuni: 156 x 234 x 17 mm

Greutate: 0.49 kg

Ediția:1

Editura: CRC Press

Colecția CRC Press

Seria Plastics Engineering

Public țintă

Professional Practice & DevelopmentCuprins

Plastics; additives; loaders and dryers; injection unit; clamp unit; mould; control; robotics and granulators; getting started; an overview - the cycle; the ten keys to successful moulding; thermoset moulding; safety; recognizing moulding problems. Appendices: injection moulding materials; properties of common plastics; recommended plastic drying data; useful data; velocity control on injection moulding machines; procedure for applications of bolt torque on nozzle adaptors (end caps).

Recenzii

". . .straightforward and practical. . .. . . .well written. . .provides the essential practical information required for successful injection modeling."

---Assembly Automation

---Assembly Automation

Notă biografică

Bernie A. Olmsted, Martin Davis

Descriere

This work focuses on the factors critical to successful injection moulding, including knowledge of plastic materials and how they melt, the importance of mould design, the role of the screw, and the correct use of the controls of an injection moulding machine. It seeks to provide operating personnel with a clear understanding of the basics of injection moulding, resulting in more efficient processing, reduced cycle times, and better part quality with fewer rejects.